Welcome to Rongda Machinery Co., Ltd

Toggle Navigation

Raw Materials! Raw Materials! Raw Materials! Important things should be repeated three times. The processing technology for biomass fuel pellets is determined by your "raw materials." First, no matter what your raw material is, the material must be powdered and the particle size should roughly match the diameter of the pellets before entering the pellet mill. Secondly, the moisture content of the raw material must be between 10% and 15%. Based on these two conditions, and in combination with the required production output, we will design the appropriate processing technology for your production.

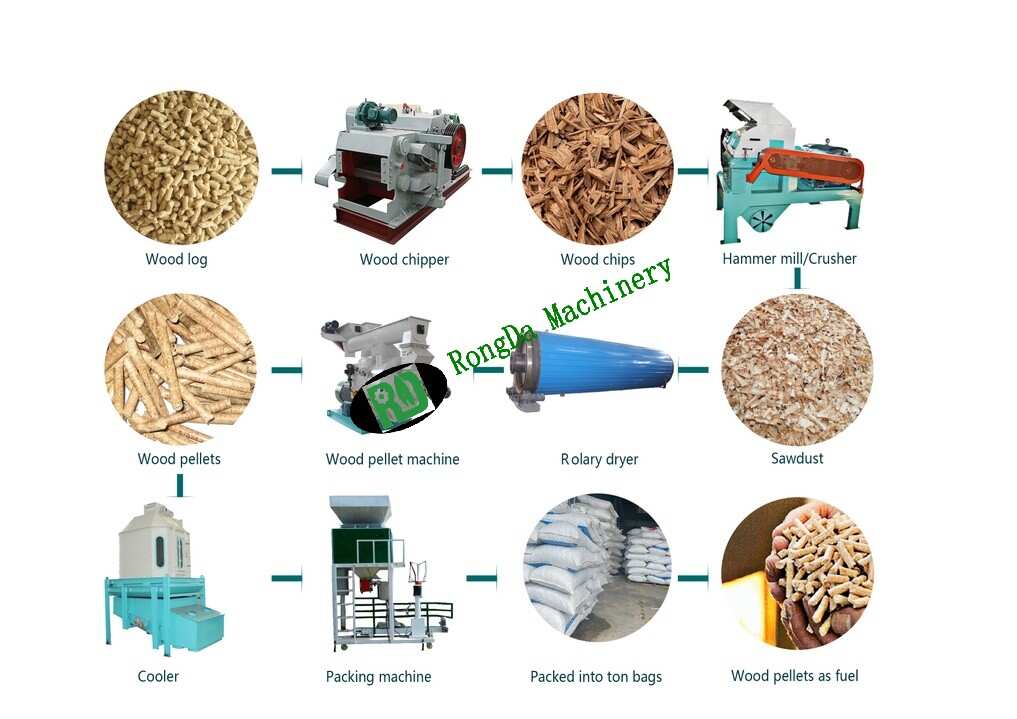

Overview of Biomass Fuel Pellet Production Process

With over 20 years of experience in production, design, and installation, and feedback from tens of thousands of customers worldwide, we have built the foundation and guarantee for our process design. A scientifically reasonable process plan is the key factor in producing high-quality products. It can not only improve production efficiency but also reduce production costs. Rongda Machinery always keeps up with the trends of modern industrial design and development, continuously innovating and researching new processes and equipment. Based on your material, production output, factory space, and other factors, we will customize a scientific and reasonable production process for you.

Production Process: Crushing and Grinding Section → Drying Section → Pelletizing Section → Cooling Section → Packaging Section

Main Equipment: The main equipment includes: Crusher, Pulverizer, Drum Screen, Mixer, Dryer, Pellet Mill, Dust Collector, Cooler, Vibrating Screen, Packaging Machine, etc.

Auxiliary Equipment: Conveyor, Iron Remover, Raw Material Bin, Finished Product Bin.

Biomass Pellet Production Process: Sawdust, rice husk, peanut shell, mushroom residue, and other powdered materials.

This process can be configured with one or more centrifugal high-efficiency pellet mills depending on the production capacity. A dryer is selected based on the moisture content of the material.

Biomass Pellet Production Process: Branches, waste wood, furniture factory offcuts, wooden strips, cotton stalks, etc.

This process requires a crusher and pulverizer. Materials with higher moisture content need to be equipped with a dryer. For pelletizing, it is recommended to configure multiple pellet mills.

Biomass Pellet Production Process: Demolition materials, plywood, old construction templates, wooden pallets, etc.

This process uses our company's patented crusher-pulverizer integrated machine. The crushed material can be directly pelletized.

Biomass Pellet Production Process: Corn stalks, rice straw, grass, and other types of straw.

The material is first crushed using a rotary cutting machine or pulverizer. The crushed material is then pelletized, cooled, and packaged.