Welcome to Rongda Machinery Co., Ltd

Toggle Navigation

This plan is applicable to small Straw pellet production lines.

Construction Nature: New Construction

Construction Scale: Annual Production of 12,000-14,400 tons of pellets

Shift System and Labor Quota:

After completion and commissioning, the labor quota is set at 8 workers.

The production will operate on a single-shift system, with each shift lasting 8 hours.

The production days per year are 300 days.

Production Line | Output | Area |

Straw pellet Production Line | 5-6 tons/hour | 97m * 29m * 25m (L * W * H) |

Capacity: 5-6 tons/hour

Raw Material: Straw

Application: Greenhouse Heating

Transformer: ≥580kVA

Raw Material Consideration:

Assess the quality, price, and quantity of raw materials, as well as the long-term supply potential. Long-term control over raw material supply is critical for stable production. With this in mind, you can plan the production line configuration and analyze the raw material cost.

Determine the Factory Location:

After confirming the raw materials, the next step is to identify the location for the factory. The ideal location should be near the raw material source or have convenient transportation access. Ideally, both factors should be considered to maximize efficiency and reduce transportation costs.

Energy Consumption:

The pelletizing industry consumes a large amount of electricity. Once the production capacity is determined, choose a transformer with an appropriate power rating based on the equipment's power consumption provided by the manufacturer. This ensures that the energy needs of the production line are met without overloading.

Purchase Equipment:

Before purchasing equipment, thoroughly research the quality of the equipment offered by manufacturers. In today’s online environment, it can be challenging to distinguish the quality of products. It’s essential to choose reliable suppliers with proven track records.

Installation and Commissioning: Once equipment is purchased, it is crucial to ensure proper installation and commissioning. Manufacturers or third-party experts should be involved in the installation and testing phases. Companies like Rongda often provide technical personnel to guide the setup, ensure the equipment functions properly, and offer training for your team.

By following these steps, you can ensure the smooth setup of a biomass pellet production line that is both efficient and cost-effective.

Construction Nature: New Construction

Construction Scale: Annual Production of 12,000-14,400 tons of pellets

Shift System and Labor Quota:

After completion and commissioning, the labor quota is set at 8 workers.

The production will operate on a single-shift system, with each shift lasting 8 hours.

The production days per year are 300 days.

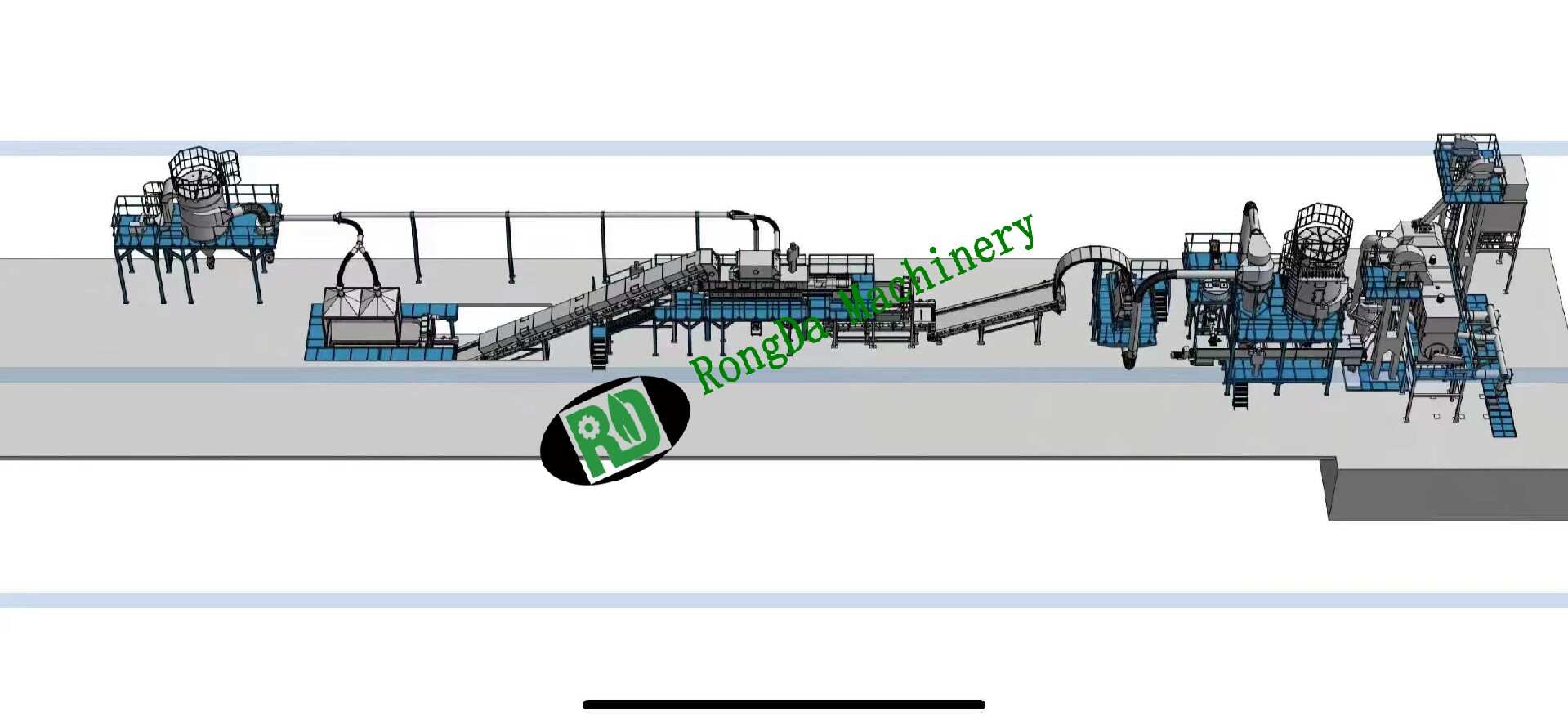

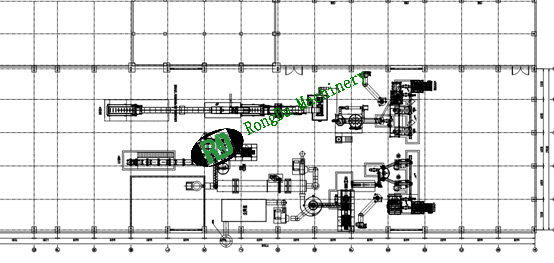

Production Line Layout Diagram:

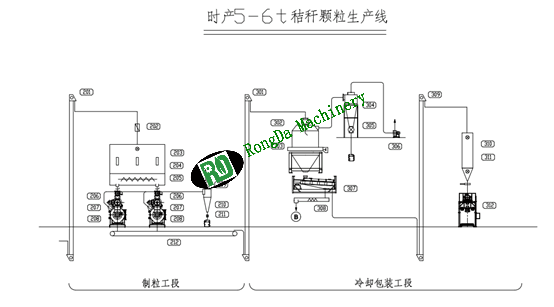

Process Flow Diagram:

项目核心设备:

The name of the device | Model | yield | power consumption | |

|

Biomass Pellet Mill |

RD-768MX | 3-3.5 |

250KW |

Pendulum cooling machine |

SKLB4

| 10 |

1.5KW | |

Rotary Screen |

SFJH130x1d

| 8-10 |

5.5KW | |

Other equipment | Conveying equipment/ / |

Customer’s Main Raw Material: Straw

Does it include a packaging system (Y/N): Yes, it is included in the complete product line.

Does it include a boiler system (Y/N): No boiler

Is it a customized solution? (Y/N): Yes, this is a customized plan.

Scope of the Project: This production line is used to produce Straw pellet.

Project Installation Duration: 20 days

Required Installation Personnel: 5 people

Service Support: (No modification needed)

Drawings:

Flowchart

Installation drawings

Operating manual

Workshop Straw pellet production line layout

Equipment installation drawings

Steel frame installation drawings

Detailed steel structure drawings and material list

Available for immediate download

Will the customer inspect the factory (Y/N): Online payment and order placement

Issues during installation process:

Rongda’s professional installation team can assist the customer with installation and resolve any issues that arise during the installation process.

One-stop After-Sales Service:

Two technical and installation engineers will be sent to guide the installation.

After installation and debugging, we will provide training for the customer's workers on how to operate the equipment.

The training will include how to maintain and protect the equipment.

Based on functionality, we will develop complete maintenance guidelines for you, including how, when, and by whom maintenance should be performed.

Our after-sales department will regularly call customers to check on maintenance status and offer advice.

Except for consumable parts, we provide a one-year free warranty and lifetime free technical support.