Welcome to Rongda Machinery Co., Ltd

Toggle Navigation

With the global emphasis on sustainable development, biomass energy, as a green and environmentally friendly energy, has gradually become the focus of people's attention. Biomass pellet machine, as an important equipment for converting biomass raw materials into high-efficiency energy pellets, has played a vital role in promoting the utilization of biomass energy.

With the global emphasis on sustainable development, biomass energy, as a green and environmentally friendly energy, has gradually become the focus of people's attention. Biomass pellet machine, as an important equipment for converting biomass raw materials into high-efficiency energy pellets, has played a vital role in promoting the utilization of biomass energy.

What is a biomass pellet machine?

A biomass pellet machine is a device that processes agricultural and forestry waste (such as wood chips, straw, rice husks, weeds, sludge, etc.) into granular fuel. These biomass pellets have become an ideal choice to replace traditional fossil fuels such as coal and oil due to their high energy density, easy storage and transportation.

Working principle of biomass pellet machine

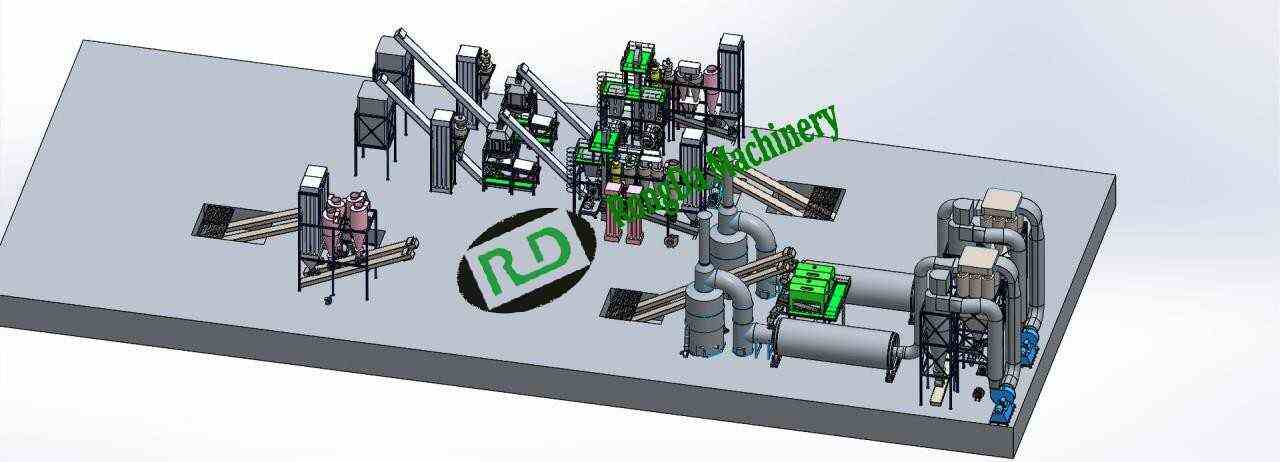

The biomass pellet machine discharges moisture and air from the raw materials through compression and heating to form dense pellet fuel. The equipment usually includes a feeding system, a pressing system, a cooling system, and a screening system. The feeding system evenly feeds the raw materials into the pressing cavity, and compresses the materials into pellets through the high pressure of the pressing roller and the ring die. After the pressing is completed, the pellets are cooled by the cooling system, and the unqualified pellets are screened out by the screening system, and finally the finished product is obtained.

Advantages of biomass pellet machine

High efficiency and energy saving: The biomass pellet machine uses abandoned agricultural and forestry resources as raw materials, with low energy consumption in the production process, and the produced pellet fuel has high combustion efficiency and high calorific value. It is an energy-saving and environmentally friendly equipment.

Environmental protection and emission reduction: Biomass pellet fuel produces almost no harmful gases and smoke during the combustion process, reducing the pollution to the atmosphere. At the same time, the use of biomass fuel can effectively reduce dependence on fossil fuels and reduce greenhouse gas emissions.

Widely applicable: The biomass pellet machine can process a variety of raw materials, including wood chips, straw, bamboo chips, palm shells, peanut shells, etc., with a wide range of applications, which can meet the needs of different regions and industries.

Easy operation: The biomass pellet machine has a compact structure and reasonable design. It is very convenient to install, operate and maintain, and is suitable for biomass fuel production enterprises of all sizes.

Rongda's biomass pellet machine

Longdun Chuhai provides a variety of models of biomass pellet machines to meet the needs of different customers. Our pellet machines have compact structure, beautiful appearance, easy operation and maintenance, and reliable equipment performance. In particular, our pellet machines adopt advanced technologies such as variable frequency speed feeding, extended conditioner, door cleaning, external discharge, overload protection, etc., and use imported bearings and oil seals in the reducer, and the transmission part adopts serpentine spring coupling to ensure the efficient operation and long life of the equipment.

Whether it is wood chips, straw, weeds, or other mixtures, Longdun's biomass pellet machines can efficiently process and produce high-quality pellet fuel that meets market demand. Our products include multiple models, from RD-350MX to RD-915MX, with production capacities ranging from 0.5 tons to 5.5 tons per hour, which can be customized according to the specific needs of customers.