Welcome to Rongda Machinery Co., Ltd

Toggle Navigation

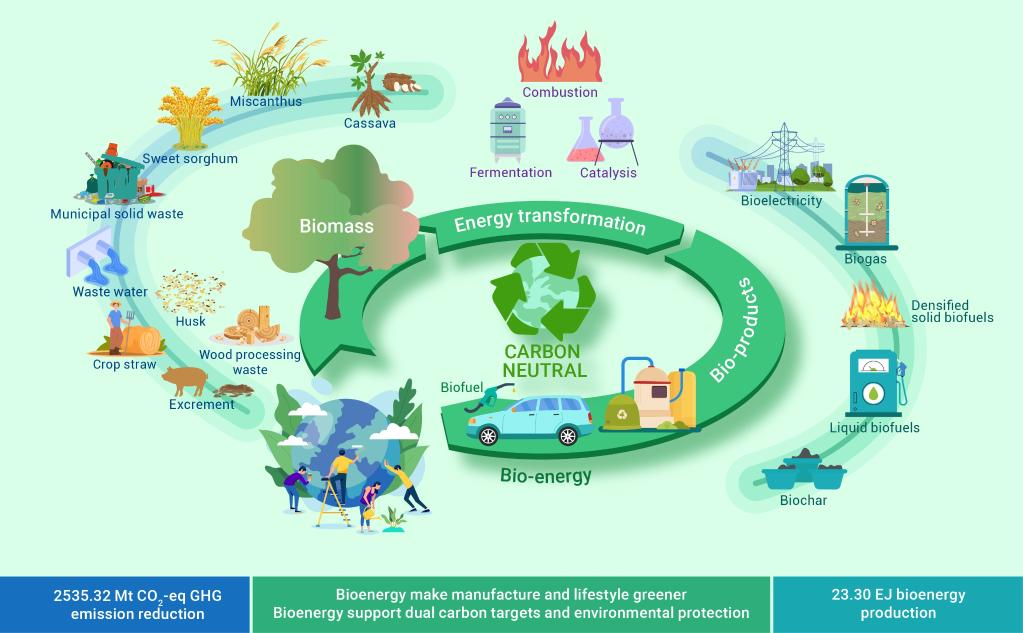

Biomass energy refers to the energy that is fixed on the earth by the photosynthesis of plants, converted into the form of biological material on the earth through the biological chain, and processed to provide raw materials for social life.

Biomass energy refers to the energy that is fixed on the earth by the photosynthesis of plants, converted into the form of biological material on the earth through the biological chain, and processed to provide raw materials for social life.

Biomass pellet fuel is a granular fuel made of wood chips, bamboo chips, tree branches, etc., which is compressed and molded at high pressure and low temperature without any chemical additives through professional machinery and special technology. Biomass pellet fuel has high calorific value, is clean and pollution-free, and is a high-tech and environmentally friendly product that replaces fossil energy.

The CO2 released by biomass pellet fuel when it is burned is roughly equivalent to the CO2 absorbed by photosynthesis during its growth, so the greenhouse gas CO2 emission of biomass pellets is zero.

Biomass fuels are renewable energy sources. As long as sunlight exists, the photosynthesis of green plants will not stop, biomass energy will not be depleted, and greenhouse gases will maintain a dynamic equilibrium. There are no environmental pollution problems.

The processing procedure of biomass pellet fuel is as follows: raw material crushing – raw material screening – drying – high temperature pressing and forming – cooling – packaging.

Biomass pellet fuel combined with the bio-boiler or burner developed by our company can replace the existing fossil energy and secondary energy such as coal, oil, gas, electricity, etc., and provide system transformation projects for industrial steam boilers, hot water boilers, indoor heating fireplaces, etc. Under the premise of the most energy-saving available, it will save more than 30% of the energy consumption cost for the user.

The service objects are: factories and enterprises with heating needs (electroplating, hardware, spraying, ceramics, garment printing and dyeing, aluminum profile processing, shoe sole factory, etc.), star-rated hotels, large general hospitals, high-end office buildings, universities, etc.

According to different raw materials, the current pellet products are divided into: fir particles, pine particles, and straw particles. After the professional testing of SGS, an international authoritative testing organization, all indicators of wood pellet fuel products have reached the highest standards of the European biomass pellet fuel industry. The DIN test results are shown in Table 1:

Metric values | Cedar wood grain | Pine Tree Granules | Straw pellets | 欧标(DIN51 731) |

Calorific value(MJ/kg) | 19.42 | 19.86 | 16.38 | 17.5 |

Calorific value (kcal/kg) | 4646 | 4751 | 3919 | 4187 |

Moisture content (%) | 8.7 | 9.2 | 8.4 | <12 |

Density (kg/m3) | 1.22 | 1.23 | 1.12 | 1.0-1.4 |

Ash Content (%) | 0.9 | 1.01 | 12.5 | <1.5 |

Sulphur content (%) | <0.03 | <0.02 | <0.06 | <0.08 |

Nitrogen content (%) | 0.16 | 0.16 | 0.24 | <0.3 |

Chlorine content (%) | 0.002 | 0.002 | 0.002 | <0.03 |

Table 2: Comparison of calorific values and costs of various fuels

serial number | Fuel type | unit | Calorific value (kcal) | thermal efficiency | Take advantage of the calorific value | Price (RMB/kg) | Heat cost (kcal/RMB) |

1 | fuel oil | litre | 11000 | 90% | 9900 | 7 | 1414 |

2 | Coal 1 | KG | 5000 | 65% | 3250 | 1.1 | 2955 |

3 | Coal 2 | KG | 7000 | 75% | 5250 | 1.5 | 3500 |

4 | liquefied gas | kg | 11000 | 90% | 9900 | 5.8 | 1707 |

5 | Natural gas | cube | 8300 | 90% | 7470 | 5 | 1494 |

6 | electricity | degree | 860 | 90% | 774 | 0.8 | 968 |

7 | Biomass pellets | KG | 4300 | 80% | 3440 | 1.2 | 2867 |

Table 3: Table of energy consumption for one ton of steam boiler by fuel type

Fuel name | diesel fuel | natural gas | electricity | Biomass pellets |

Calorific value (Kcal) | 11000 | 8300 | 860 | 4300 |

Fuel price (yuan) | 7.3 | 5 | 0.8 | 1.2 |

Energy consumption per ton of steam | 73(Kg) | 96(M3) | 900(KWH) | 220(Kg) |

Cost per ton of steam | 532.9 | 480 | 720 | 264 |

relative to the cost of biomass | 201.86% | 181.82% | 272.73% | 100.00% |