Welcome to Rongda Machinery Co., Ltd

Toggle Navigation

【Case】12 tons/hour granule production line

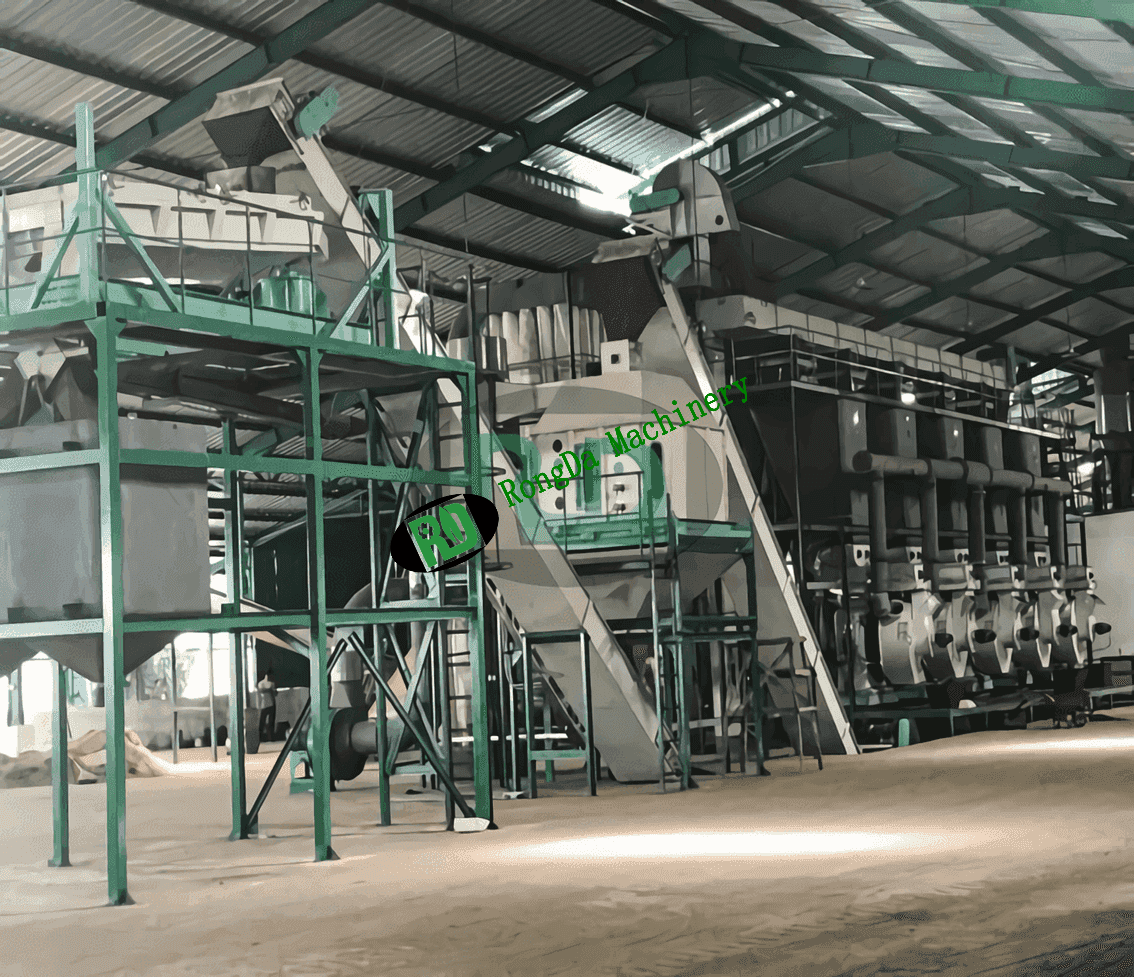

The customer is a pellet factory in Indonesia.

Nature of construction: new

Construction scale: annual output of 50,000 tons of granules

Number of installers required: 10 people

The production line operators: 7-8 people

| country | Time | production line | Yield | area |

| Indonesia | 2018.6.17 | Wood pellet production line | 12 tons/hour | As per the design drawing |

Indonesia 12 tons/hour wood pellet production line solution

Capacity: 12 tons/hour

Raw material: sawdust / wood / sawdust / shavings

Applications: Industrial boilers/biomass power plants/wood processing/home fireplaces

:≥2700kVA。

How to build a biomass pellet production line?

Examine the quality, price, and quantity of raw materials, and also consider the factors of long-term supply (i.e., long-term control), so that we can plan the configuration of the production line and analyze the cost of raw materials according to the configuration of the production line. Once the raw materials have been decided, it is necessary to determine the plant. The construction of the plant or looking for a place that is generally close to the raw material or convenient transportation. It's best to have both. Energy consumption. The pelletizing industry consumes a lot of electricity. After determining the production capacity, purchase a transformer that matches the production capacity according to the equipment power selection provided by the equipment manufacturer. Purchase equipment. Before buying equipment, you must first understand the product quality of the equipment manufacturer. In the network environment, it is often difficult to distinguish between good and bad product quality. For equipment installation and commissioning, Rongda will send technical personnel to provide guidance, installation, commissioning and training.

【Case】12 tons/hour granule production line

The customer is a pellet factory in Indonesia.

Nature of construction: new

Construction scale: annual output of 50,000 tons of granules

Number of installers required: 10 people

The production line operators: 7-8 people

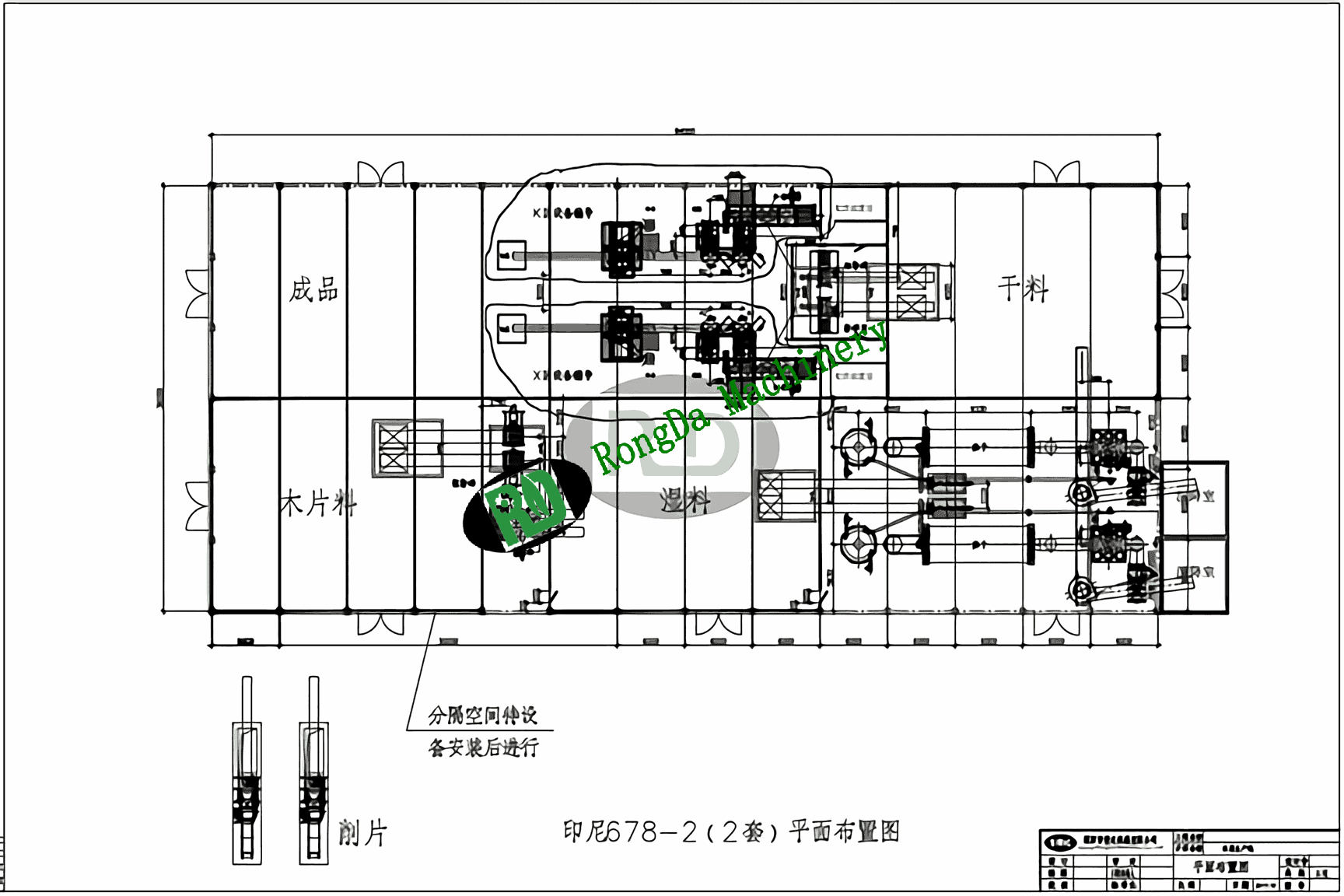

Production line design drawing:

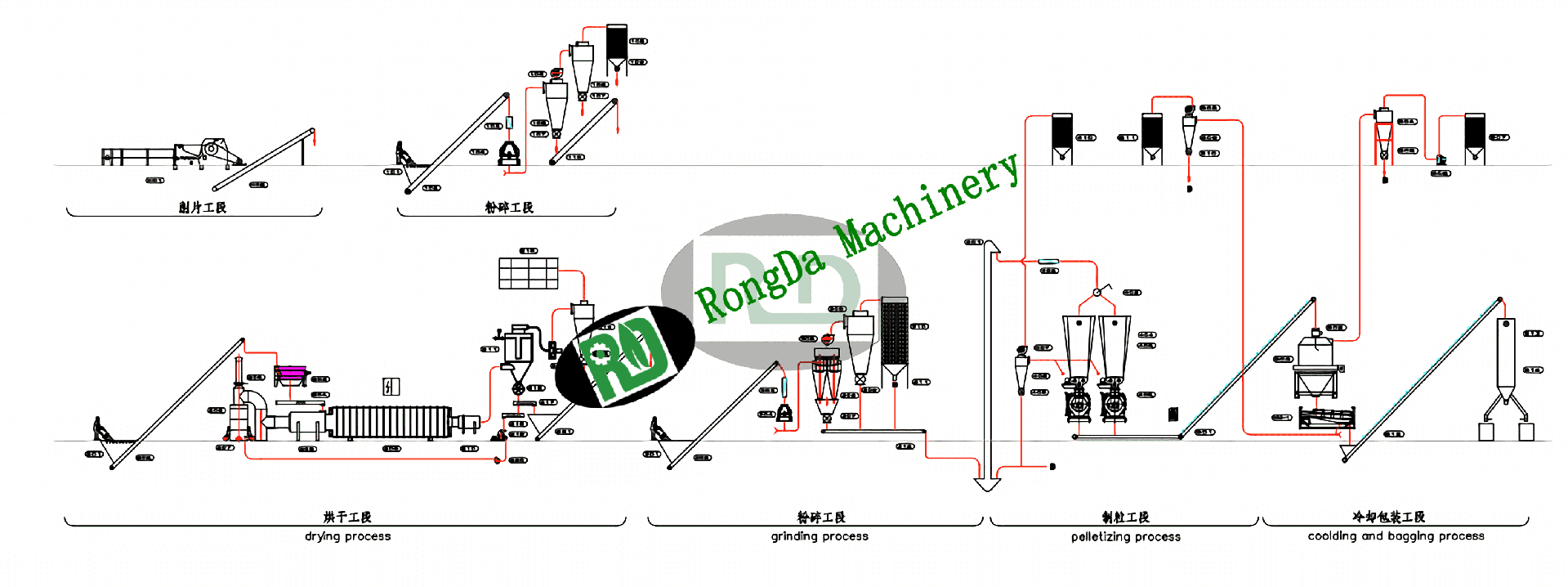

Process:

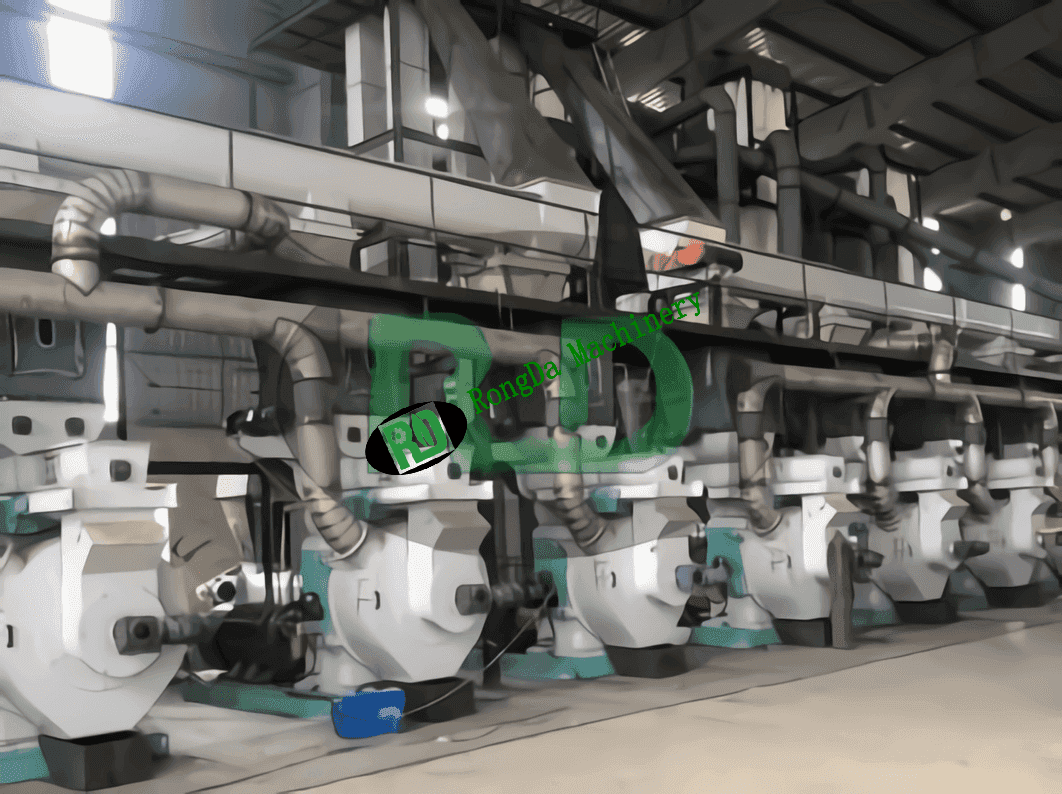

The core equipment of the project:

| The name of the device | Model | Yield | power consumption | |

| 5-6 | 191 | ||

| 20-25 | 60.00 | ||

| 5-7 | 160.00 | ||

| 4-5 | 3.0×4 | ||

| 8-15 | 7.5KW | ||

| 5-6 | 1.50 | ||

| Other equipment | Packing machine/transport system/electric control/dust removal | |||

The core equipment of the project:

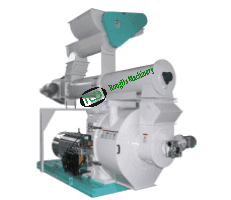

1. RD678MX granulator * 191KW;

2. Peeling machine * BP25x120;

3. Crusher * SFSP65x120;

4. Drying machine* Φ 2.6x9m;

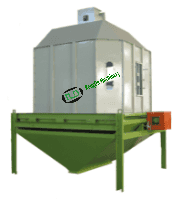

5. Cooler*Schlan6;

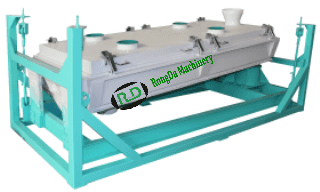

6. Classification screen * SFJH150 × 1d;

7. Electric control cabinet;

8. Packing machine and other auxiliary equipment

Customer's main raw material: wood/wood chips

Customer demand finished product size: 8-10mm, output humidity 12-15%.

Packaging system included (Y/N): Yes, this is included in the complete product line

With or without boiler system (Y/N): No boiler

Is it a custom solution?(Yes/No): Yes, it's a custom plan.

Scope of application: This production line is used to produce wood pellets

The installation period of this project is 60 days

The number of installers required: 10 people

Service Support:

Drawing:

Flow chart;

installation drawings;

operating instructions;

Layout of wood pellet production line in workshop;

Equipment installation drawing;

steel bracket installation drawing;

Detailed steel structure drawings and bill of materials

Whether the customer comes to the factory to check (yes/no): pay online and place an order

Problems in the installation process: The installation team can help customers install and solve problems in the installation process.

One-stop after-sales service:

send two technical installation engineers to guide the installation. After the installation and commissioning are completed, we have carried out operation training for the customer's workers;

Train staff on how to maintain and protect, and depending on the function, we will develop complete maintenance rules for you, including how, when, and by whom.

Our company's after-sales department will call customers regularly to inquire about the maintenance situation and provide suggestions. In addition to wearing parts, our company also provides one-year free warranty and permanent free technical support.