Welcome to Rongda Machinery Co., Ltd

Toggle Navigation

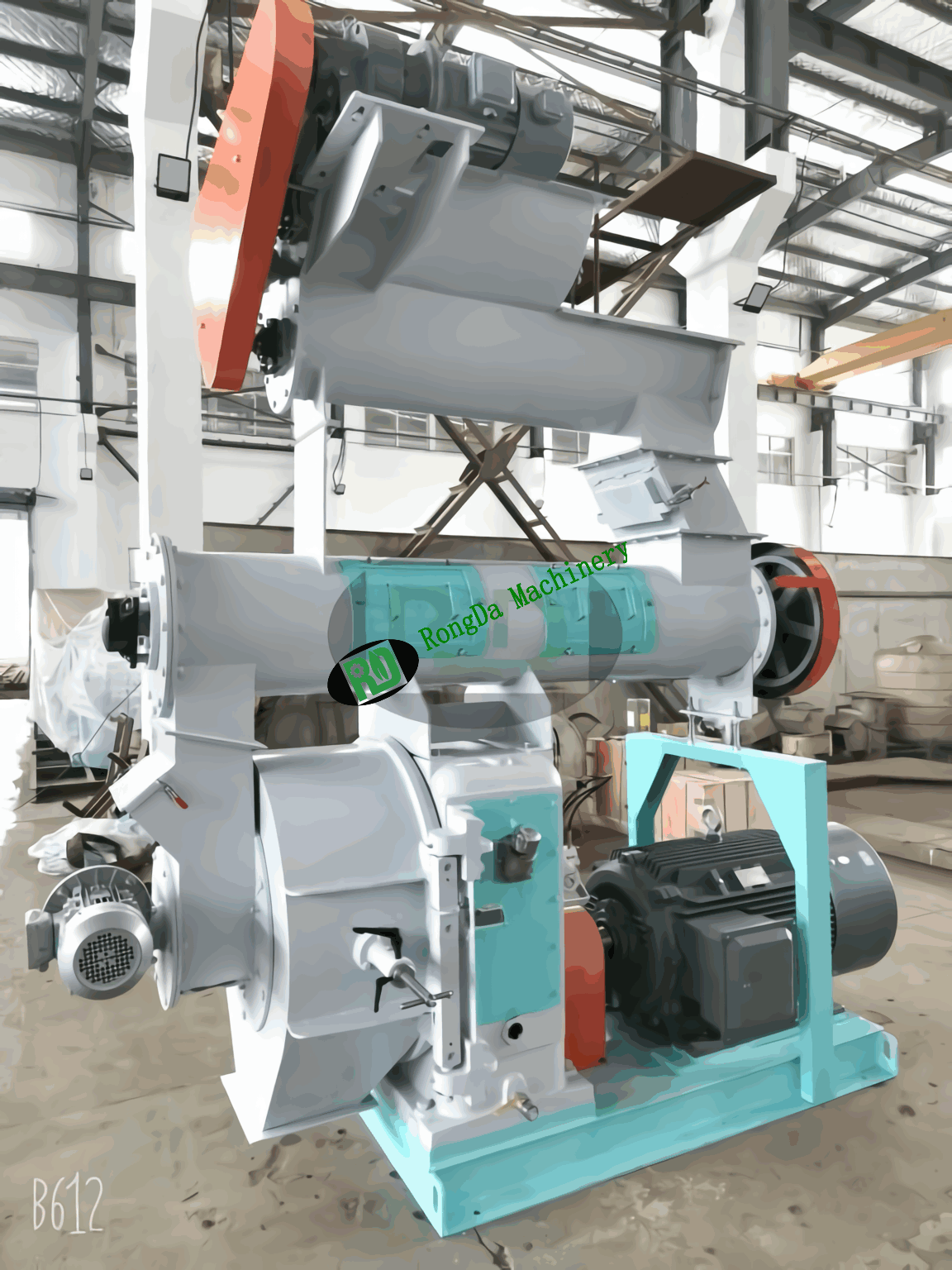

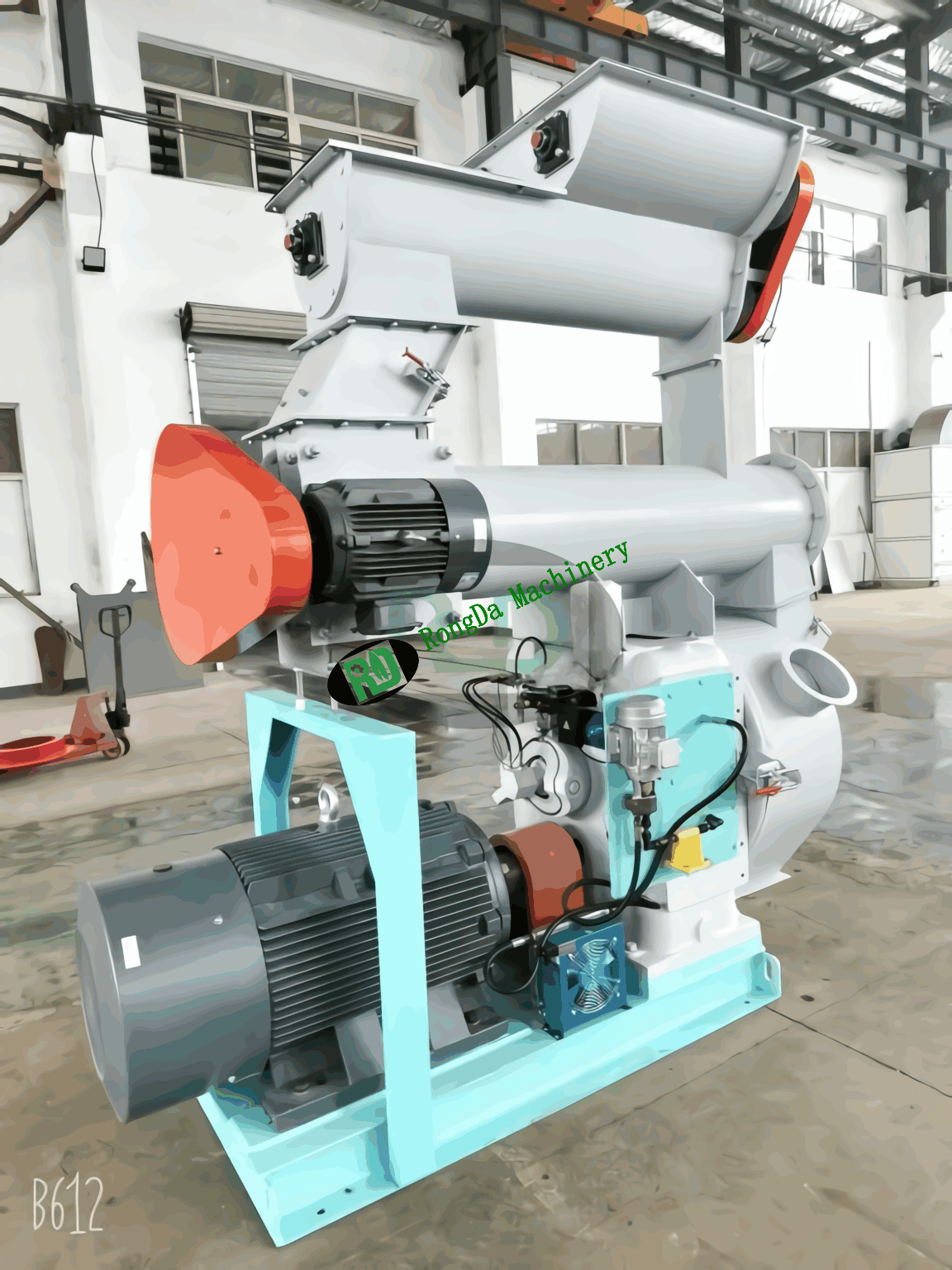

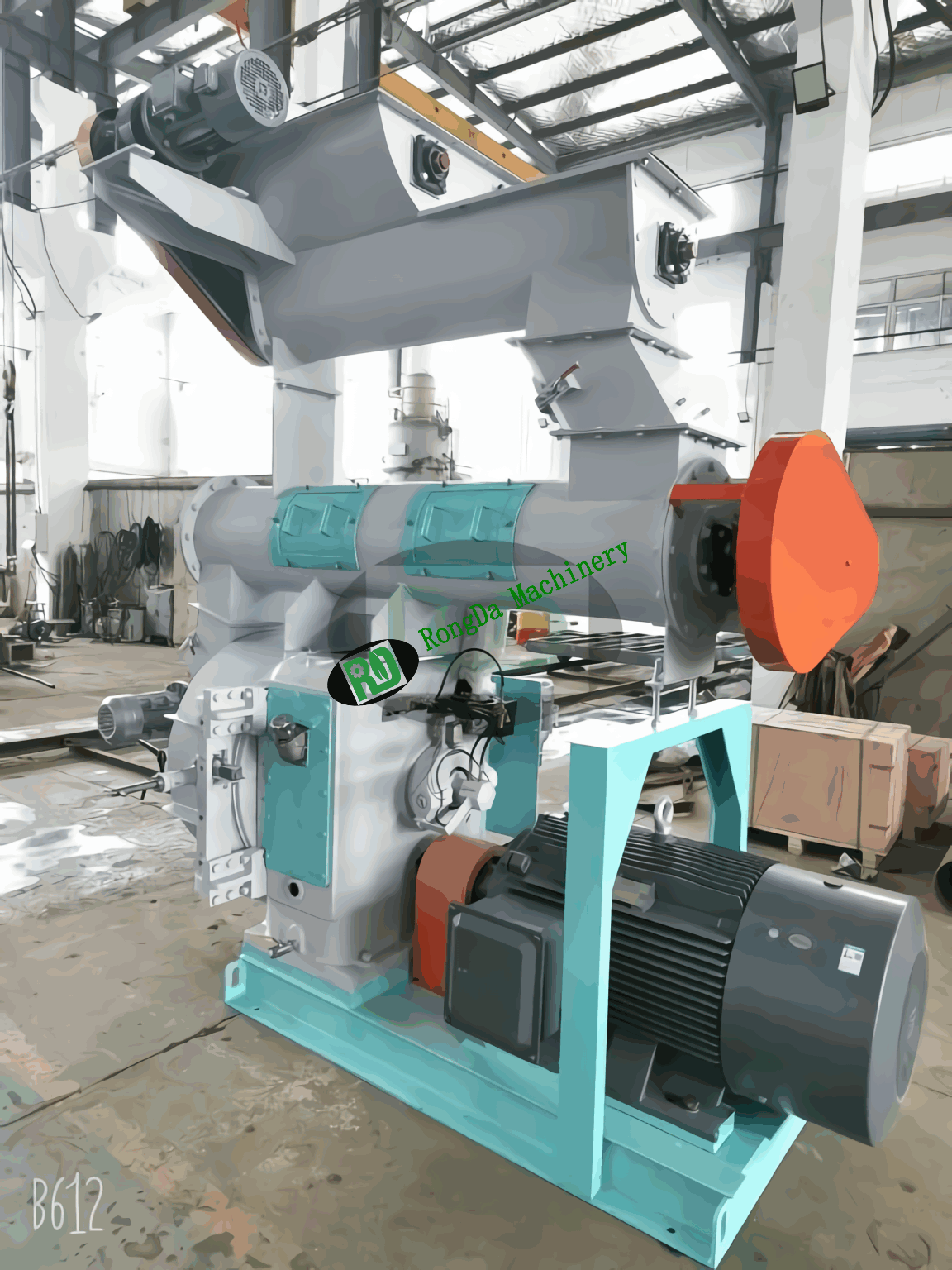

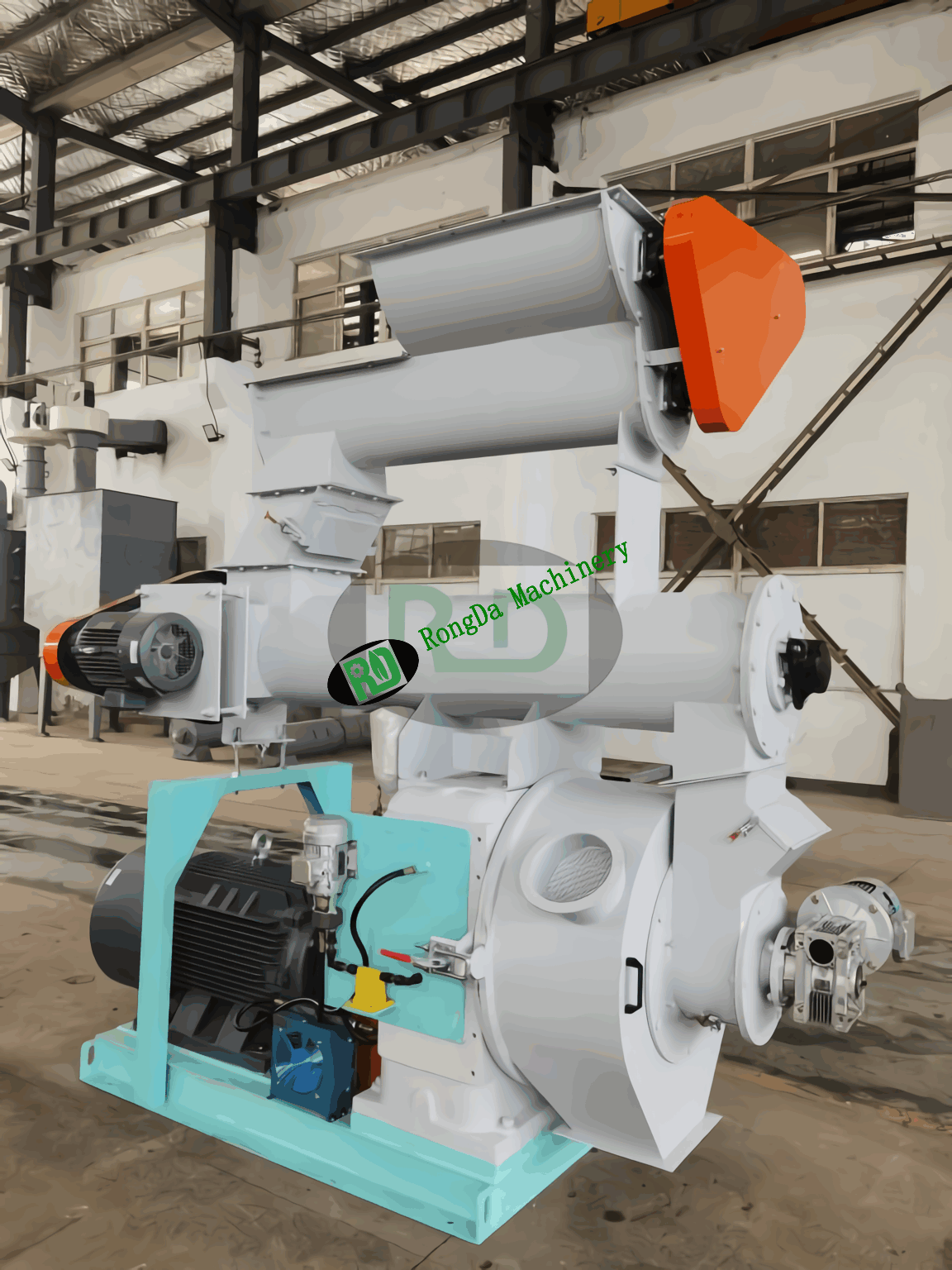

The RD-480MX Biomass pellet mill is a high-performance granulator with a compact structure, beautiful appearance, and easy installation, operation, and maintenance. The machine has customizable ring die apertures (Φ6, Φ8, Φ10) and adopts frequency conversion speed regulation feeding, extended quality adjuster big door cleaning method, and set organic discharge and overload protection device. The transmission box uses imported bearings and oil seals, ensuring stable operation. The machine has a main power of 90KW-110KW, producing 6-12mm particles at 1.2-1.5T/H with a die diameter of 480mm. The company, Rongda Machinery, offers high-efficiency granulators that turn high-fiber waste Bagasse into high-quality wood pellet fuel, with a high output of 2.5-3t/h.

Model: RD-480MX

Main power: 110KW

Pellet Size: 6-12mm

Capacity: 1.2-1.5T/H

Die Diameter: 480mm

Custom: Made Customizable

1.This machine is suitable for small biomass pellet processing plants. The capacity is 1.2-1.5 ton per hour. This model of pellet mill is equipped with automatic lubrication system and die-hoisting device. This machine doesn’t need worker to add grease and operation and maintenance are very convenient.

2.According to the characteristics of biomass raw materials, we have made a special design for the main gear & pinion shaft, and handed to a professional gear factory to complete the processing which makes the main gear & pinion shaft with high precision and long service life.

3.5 sets bearings in gearbox are FAG bearings imported from Germany; the main shaft and the combined quill shaft in gearbox are forged with 42CRMO materials whose strength and wear resistance are better than ordinary materials and is more durable; the main components and the gearbox are processed by high-precision CNC machine to ensure the high-precision cooperation of the components, greatly improve the service life of the machine.

4.In response to the poor fluidity of various agricultural and forestry wastes, we have installed a force-feeding system in front of the pelletizing chamber, so that raw materials can easily enter the pelletizing chamber and be pressed. The feeding conveyor is also equipped with the arch breaking device and a variable frequency motor that can adjust the material flow speed, so that the material can enter the pelletizing chamber very smoothly.

5.At the same time, in view of the characteristics of light gravity of biomass raw materials and more ash, we add a sealing device between the door cover and the pelletizing chamber, so that the dust is not easy to leak. The door cover and forced feeder are made of stainless steel to avoid the corrosion of hot steam during pelletizing. The door cover also adds a collection inlet device for hot steam in the pelletizing process, which can be extracted from the hot steam in the pelleting chamber by increasing the dehumidification device, greatly reducing the heat of the pelleting chamber. Thus prolong the service life of the roller bearing.

6.All our pellet mills are equipped with safety devices. If there are small iron nails or too dry and wet raw materials in the pelletizing process, which makes pelleting very difficult, the machine will break the shear pin by itself and force the main motor to stop running to protect the machine from further damage. Therefore, our machine has low failure rate, good stability, low operating cost, high pellets density and good forming degree, which is worth your own.