Welcome to Rongda Machinery Co., Ltd

Toggle Navigation

Ever thought about ditching traditional fuels for something greener? Wood pellet machines might just be your ticket to a more sustainable lifestyle—or even a side hustle. These nifty devices turn raw wood into compact, energy-packed pellets that can heat your home or power a business. Let’s dive into what makes these machines so cool, how they work, and how to pick the right one without sounding like a textbook.

Wood pellets are like nature’s answer to coal or gas. They’re made from compressed wood scraps—think sawdust or wood chips—and burn cleaner than fossil fuels. Why’s that a big deal? Because they’re carbon-neutral. The carbon they release when burned is roughly what the tree soaked up while growing. Plus, pellets are often cheaper than oil or propane, especially if you’re making them yourself. Imagine firing up your fireplace with pellets you made in your garage—pretty satisfying, right?

Okay, let’s get to the nuts and bolts. A wood pellet machine takes raw wood and transforms it into those dense little pellets. Here’s the gist:

Grind it: The machine chews up wood into a fine powder, like sawdust on steroids.

Dry it: Too much moisture makes for lousy pellets, so the machine dries the powder to just the right level.

Squish it: A die and roller system (the heart of the pelletizing process) compresses the dry powder into tight, uniform pellets.

Cool and pack: The fresh pellets cool off and are ready to bag up or burn.

It’s like making pasta, but instead of noodles, you get fuel. Simple, yet brilliant.

Not all pellet machines are created equal. Here’s a quick rundown of what’s out there:

Home-use models: These are compact, user-friendly machines perfect for DIY enthusiasts or small businesses. They’re great for whipping up enough pellets to keep your home cozy or sell locally.

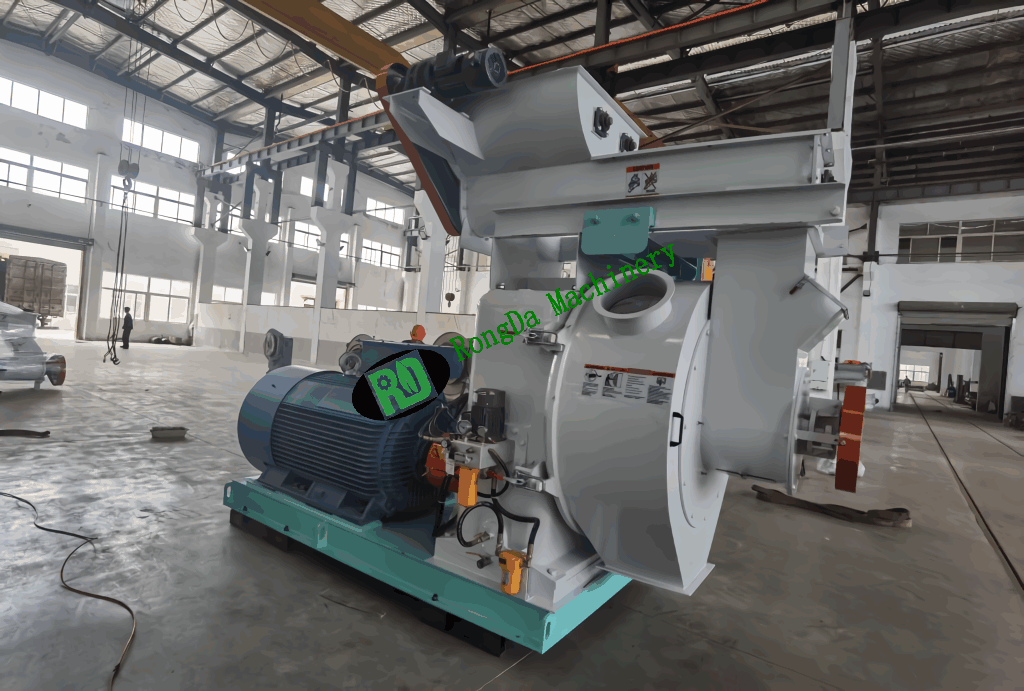

Industrial beasts: Built for big operations, these machines churn out pellets by the ton. Think factories or large farms feeding biomass materials into the mix.

Pelletizing units: These vary in size but use that same die-and-roller magic. They’re versatile enough for both home and commercial setups, depending on the model.

Choosing a machine can feel like picking a car—overwhelming but exciting. Here’s what to keep in mind:

How much do you need? If you’re just heating your house, a small residential machine will do. Planning to sell pellets at the farmer’s market? Go for something with more muscle.

What’s your raw material? Some machines are picky about what they process—wood chips, sawdust, or other biomass materials like straw. Make sure your machine matches what you’ve got on hand.

Automation or hands-on? Fancy a machine that does most of the work for you? Automated models save time but cost more. If you’re on a budget, manual controls might be fine.

Energy efficiency: Look for a machine that sips power, not guzzles it. Your wallet and the planet will thank you.

Budget reality check: Machines range from a few hundred bucks for basic models to thousands for industrial ones. Factor in maintenance and electricity costs too.

Pro tip: Don’t just buy the first machine you see. Check reviews, compare brands, and maybe even ask other pellet makers for their two cents. Oh, and think ahead—if your pellet-making hobby turns into a business, can your machine keep up?

Besides the warm fuzzies of going green, there’s real value here. Pellets can slash your heating bills, especially in chilly climates. For businesses, selling pellets can be a nice revenue stream. And let’s not forget the environment—fewer fossil fuels mean less air pollution. It’s a win-win-win.

Here’s a quick look at a few standout wood pellet machines (no, I’m not selling them, just sharing the love):

XYZ Manufacturing’s Model A: A powerhouse for industrial use. It’s energy-efficient, automated, and pumps out pellets like nobody’s business. Perfect for big manufacturers.

ABC Industries’ Model B: Small but mighty, this one’s great for homeowners or small shops. Low maintenance and easy to set up.

DEF Corporation’s Model C: A jack-of-all-trades that handles different biomass materials. Built to last and quiet as a mouse.

GHI Tech’s Model D: High-tech and precise, this one’s for folks who want top-quality pellets and customizable settings.

JKL Solutions’ Model E: Tech-savvy with remote monitoring and energy-saving features. Ideal for modern setups looking to streamline.

Wood pellet machines are your gateway to cleaner, cheaper energy. Whether you’re warming your home or starting a pellet-making venture, there’s a machine out there for you. Focus on what fits your needs—size, materials, budget—and you’ll be cranking out pellets in no time. Ready to make the leap? Do a little homework, and you’ll be set to join the renewable energy revolution.

What can I use wood pellets for? Mostly heating or cooking, but they’re also a renewable energy source for power generation.

What goes into a wood pellet machine? Wood chips, sawdust, or other biomass materials like agricultural waste. Check your machine’s specs for compatibility.

How do I keep my machine running smoothly? Clean it regularly, lubricate moving parts, and check for wear. A little TLC goes a long way.

Are pellets worth the cost? Absolutely. They’re often cheaper than traditional fuels, and making your own can save (or earn) you money over time.