Welcome to Rongda Machinery Co., Ltd

Toggle Navigation

You've probably heard about biomass pellets becoming a bigger deal lately. With everyone trying to cut down on fossil fuels, these little compressed fuel nuggets are showing up everywhere from home heating systems to industrial boilers. But here's the thing - making good pellets isn't as straightforward as it might seem.

That's where flat die pellet mills come into the picture. These machines have been quietly gaining ground in the pellet-making world, and there are some pretty solid reasons why.

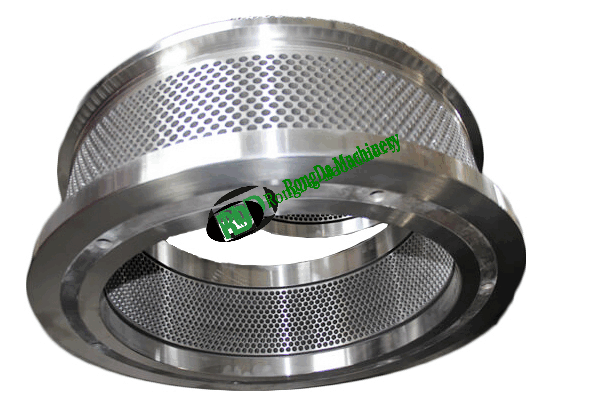

Unlike their ring die cousins, flat die pellet mills work with a horizontal compression system. Think of it like this - your raw material (wood chips, sawdust, crop leftovers, whatever) gets pressed down through holes in a flat metal plate. Simple concept, but the results can be pretty impressive.

The flat die design has some real advantages. For one thing, it's way more stable during operation compared to other setups. You're not dealing with as much vibration or wear on the moving parts. Plus, most people find them easier to work with day-to-day.

Here's what I've noticed about these machines in actual use: they're surprisingly versatile. You can throw different types of biomass at them - wood waste, straw, even some agricultural residues - and they'll handle it reasonably well. That flexibility matters if you're dealing with varying raw material supplies.

The maintenance aspect is another selling point. The design is fairly straightforward, which means fewer things can go wrong. When something does need fixing, you're usually not looking at complex repairs or hard-to-find parts.

Energy consumption is where these mills really shine though. The flat die configuration tends to be more efficient than alternatives, which adds up when you're running production for hours at a time.

In terms of pellet quality, flat die mills produce pretty consistent results. The pellets come out with uniform density, which is crucial whether you're making fuel pellets for heating or feed pellets for livestock. Inconsistent pellets cause nothing but headaches - they don't burn evenly, they create dust, and customers complain.

The output rates are decent too, though they're not going to compete with massive industrial ring die systems. But for small to medium operations, they hit a sweet spot between production capacity and reasonable equipment costs.

Look, no piece of equipment is perfect, and flat die pellet mills have their limitations. They're not the best choice for every situation. But if you're looking at starting pellet production or upgrading from an older system, they deserve serious consideration.

The combination of reasonable upfront costs, manageable maintenance requirements, and solid performance makes them attractive for a lot of operations. Especially now, with the renewable energy market expanding and more people looking for alternatives to traditional fuels.

Whether you're processing agricultural waste that would otherwise get burned in fields or turning sawmill byproducts into something valuable, these mills can handle the job without requiring a massive investment or a team of technicians to keep them running.

The bottom line? Flat die pellet mills aren't revolutionary, but they're proving to be a practical solution for businesses wanting to get into sustainable fuel production without breaking the bank or dealing with overly complicated equipment.