Welcome to Rongda Machinery Co., Ltd

Toggle Navigation

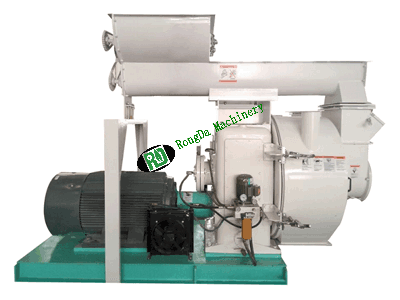

The renewable energy sector is experiencing a transformative shift, with biomass pellets emerging as a cornerstone of sustainable fuel solutions. Among these, hardwood pellets have gained exceptional prominence due to their superior energy output and environmental benefits. To meet this growing market demand, the European-standard hardwood pellet mill with 0.3-10T/H capacity represents a breakthrough in pellet manufacturing technology, offering unmatched performance for both emerging and established biomass producers.

This sophisticated pellet mill stands as a testament to precision engineering, specifically calibrated for processing dense hardwood materials including oak, maple, beech, and birch varieties. The equipment's adherence to stringent European manufacturing protocols ensures that every pellet meets premium quality standards, making it an invaluable asset for businesses prioritizing excellence in their biomass production operations.

The mill's remarkable capacity spectrum, ranging from 0.3 to 10 tons per hour, provides unprecedented operational flexibility. This adaptability makes it equally suitable for:

Startup Operations: Smaller enterprises can begin with modest production volumes and scale progressively

Industrial Applications: Large-scale manufacturers can maximize output efficiency without compromising quality

Seasonal Adjustments: Production capacity can be modified based on market demands and seasonal variations

Built with premium-grade steel components, this pellet mill showcases exceptional durability characteristics. The critical components—including the compression die, roller assembly, and transmission system—are manufactured using advanced metallurgical processes that ensure extended operational life even under demanding production conditions.

The robust construction philosophy translates into:

Minimized maintenance requirements

Reduced operational interruptions

Enhanced return on investment through extended service life

Consistent pellet quality over time

Modern manufacturing demands energy-conscious solutions, and this pellet mill delivers through innovative design features:

Advanced Drive Systems: The incorporation of variable-frequency drives allows operators to optimize power consumption based on real-time production requirements, resulting in substantial energy savings.

Efficient Power Transfer: The sophisticated gearbox design minimizes energy losses during the pelletizing process, ensuring maximum conversion of input power into productive output.

Smart Controls: Automated systems continuously monitor and adjust operational parameters to maintain optimal efficiency levels throughout production cycles.

Meeting the demanding environmental standards of European regulations, this pellet mill contributes to cleaner production processes through:

Emission Control: Advanced dust collection systems minimize particulate emissions

Resource Efficiency: Optimized processing reduces waste generation

Clean Combustion Support: Produces high-quality pellets with low moisture content and minimal ash residue

Carbon Footprint Reduction: Enables the production of renewable fuel alternatives to fossil fuels

The mill's sophisticated control systems ensure remarkable consistency in pellet characteristics:

Dimensional Accuracy: Precise die configurations produce uniform pellet sizes for optimal combustion performance

Density Control: Advanced compression technology achieves consistent pellet density, crucial for efficient fuel handling and storage

Moisture Management: Integrated conditioning systems maintain optimal moisture levels throughout the production process

Quality Assurance: Continuous monitoring systems detect and correct variations in real-time

Hardwood pellets command premium market prices due to their superior energy characteristics. This mill excels in processing various hardwood species, delivering:

Higher BTU Output: Dense hardwood pellets provide more energy per unit weight

Extended Burn Times: Consistent density ensures longer combustion periods

Reduced Ash Content: Superior raw material processing minimizes residual ash

Enhanced Storage Stability: Proper compression reduces degradation during storage

Production Range: 0.3-10 metric tons per hour capacityConstruction Materials: High-carbon steel alloys for critical wear componentsPower Efficiency: Variable-speed drives with energy recovery systemsControl Systems: Programmable logic controllers with touchscreen interfacesCustomization Options: Adjustable pellet dimensions and production parametersEnvironmental Features: Integrated dust collection and noise reduction systemsRaw Material Versatility: Optimized for various hardwood species and moisture contents

Investing in this European-standard pellet mill provides multiple competitive advantages:

Market Positioning: Ability to produce premium-grade pellets that command higher market prices

Operational Flexibility: Scalable production capacity accommodates business growth

Cost Efficiency: Reduced energy consumption and maintenance costs improve profitability

Quality Assurance: Consistent product quality enhances customer satisfaction and brand reputation

Future-Proofing: Compliance with evolving environmental standards ensures long-term viability

The European-standard 0.3-10T/H hardwood pellet mill represents more than just manufacturing equipment—it embodies a commitment to sustainable energy production and environmental responsibility. By combining cutting-edge technology with robust engineering principles, this mill enables businesses to participate meaningfully in the global transition toward renewable energy sources.

For organizations seeking to establish or expand their presence in the biomass pellet market, this mill offers an unparalleled combination of performance, reliability, and environmental stewardship. The investment not only supports immediate production goals but also positions businesses at the forefront of the renewable energy revolution, contributing to a cleaner, more sustainable energy future for generations to come.

Whether serving residential heating markets, industrial fuel applications, or export opportunities, this advanced pellet mill provides the foundation for successful, sustainable biomass production operations that meet the highest European quality standards.