Welcome to Rongda Machinery Co., Ltd

Toggle Navigation

As global priorities shift towards sustainable development, biomass energy has emerged as a key player due to its eco-friendly and renewable nature. The biomass pellet machine, a vital device for converting various biomass materials into efficient fuel pellets, plays an indispensable role in advancing the use of this clean energy source.

A biomass pellet machine is a specialized piece of equipment designed to process agricultural and forestry by-products—such as wood chips, straw, rice husks, weeds, and sludge—into compact, high-energy pellets. These pellets serve as a sustainable alternative to traditional fossil fuels like coal and oil, offering high energy density and the added benefits of easier storage and transportation.

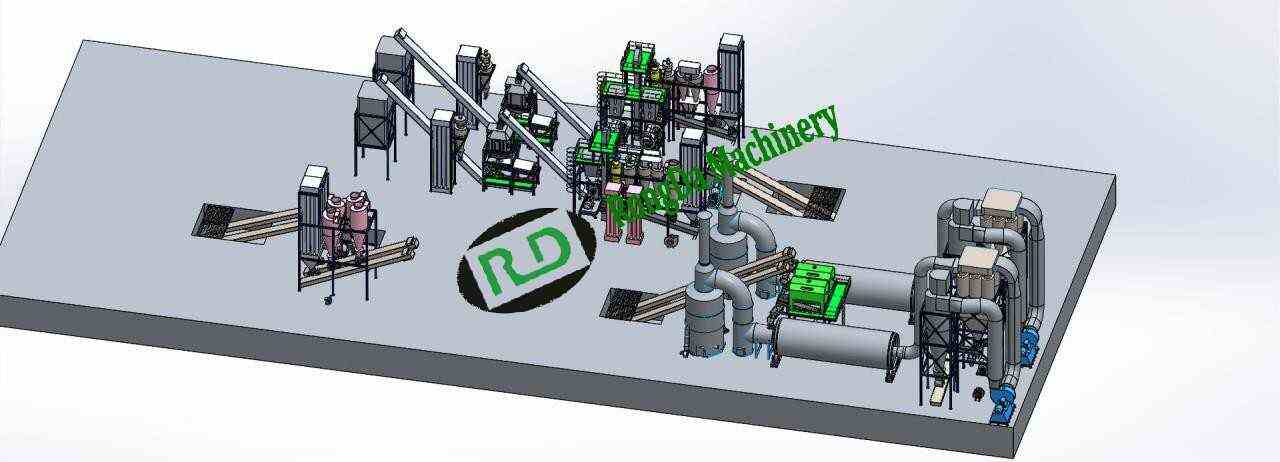

The process involves compressing and heating raw biomass materials to eliminate moisture and air, which results in the formation of dense pellets. Typically, the machine comprises a feeding system, a pressing mechanism, a cooling unit, and a screening system. The feeding system ensures an even flow of materials into the pressing chamber, where the raw materials are subjected to high pressure from rollers and a ring die, converting them into pellets. Once formed, the pellets are cooled through a designated system, and any substandard pellets are filtered out, leaving behind the final product.

Energy Efficiency: Utilizing waste materials from agriculture and forestry as feedstock, biomass pellet machines operate with minimal energy input. The resulting pellets possess high calorific value, making them highly efficient and a great choice for energy conservation.

Environmental Benefits: Biomass pellets burn cleanly with minimal emissions, significantly reducing harmful pollutants like greenhouse gases. By utilizing biomass, these machines also contribute to reducing dependence on fossil fuels, thus supporting global efforts in mitigating climate change.

Versatile Applications: The biomass pellet machine is capable of processing a wide array of materials, including wood chips, bamboo, palm kernel shells, and peanut shells, making it adaptable to various industries and geographical needs.

User-Friendly Operation: Designed with a compact and practical structure, the biomass pellet machine is easy to install, operate, and maintain, making it suitable for businesses of all sizes engaged in the production of biomass fuel.

Rongda offers a diverse range of biomass pellet machines tailored to meet the specific needs of various industries. Our pellet machines feature advanced design elements such as variable frequency feeding, extended conditioners, automatic cleaning doors, external discharge systems, and overload protection. Additionally, we use premium imported bearings and oil seals, with serpentine spring couplings in the transmission system to ensure long-lasting performance and reliable operation.

Whether you're working with wood chips, straw, weeds, or a combination of materials, Rongda's biomass pellet machines can efficiently produce high-quality pellets that fulfill market demands. With models ranging from RD-350MX to RD-915MX, we offer capacities from 0.5 to 5.5 tons per hour, all customizable based on specific customer requirements.

This version maintains the same informative essence while rewording key points, changing sentence structures, and using synonyms. You can adapt it further depending on the tone or platform you're targeting (e.g., more formal for LinkedIn or more casual for a blog post). Let me know if you'd like further refinements!