Welcome to Rongda Machinery Co., Ltd

Toggle Navigation

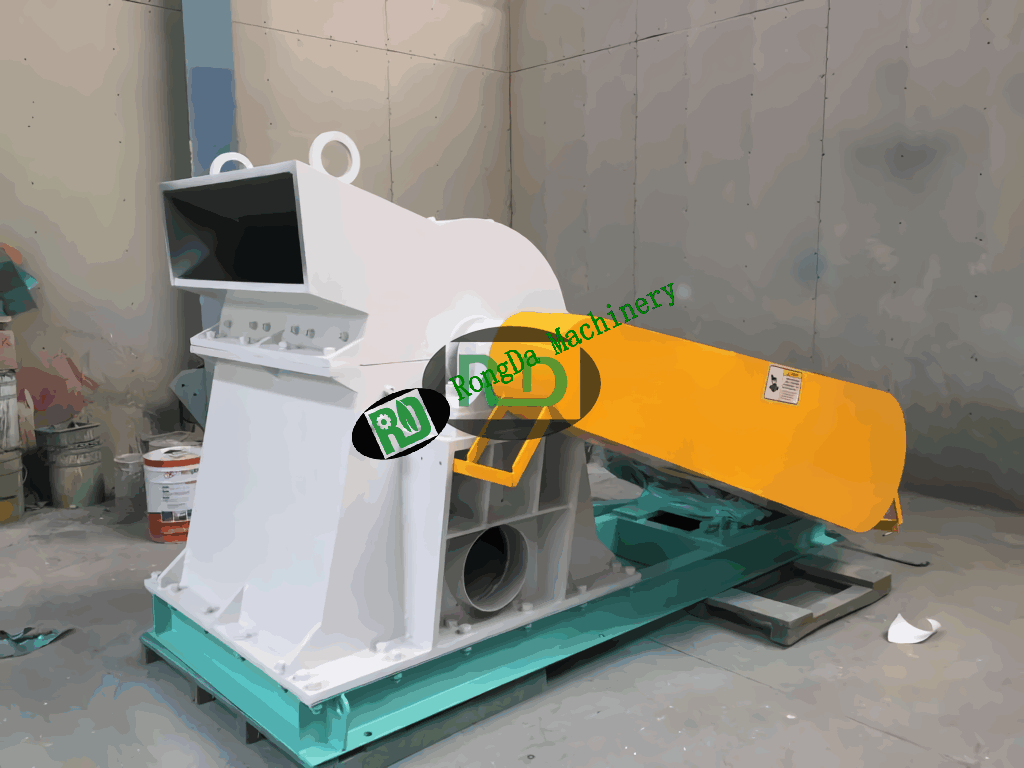

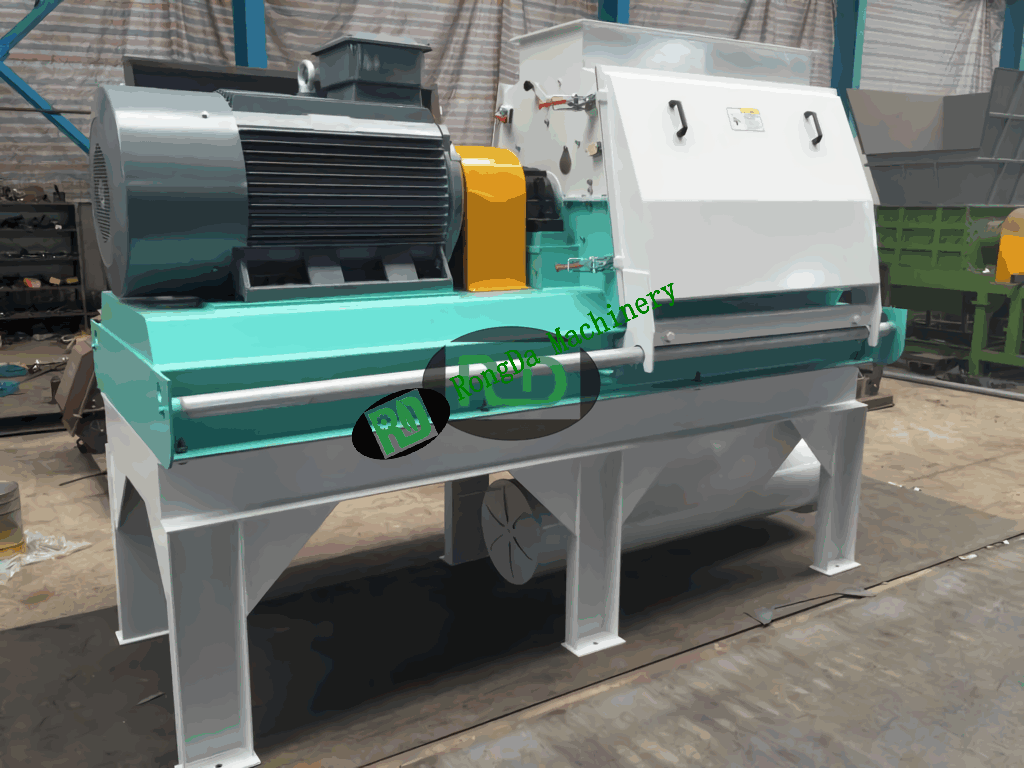

A biomass hammer mill is a key player in the world of renewable energy, especially when it comes to turning raw biomass materials into energy. If you’re looking to process biomass for biofuels, pellets, or briquettes, this powerful machine is essential for breaking down bulky materials into something useful and easy to work with.

The biomass hammer mill does its job by using mechanical power to break down biomass materials. Inside the machine, fast-moving hammers are mounted on a rotating shaft. These hammers smash the material against a perforated screen, which reduces it to smaller particles. This high-impact process works for a range of materials, from wood chips to agricultural waste and other organic matter.

One of the biggest advantages of using a hammer mill is its versatility. Unlike other types of mills, it can handle a variety of materials with different moisture and density levels. Whether the material is dry, damp, light, or dense, the hammer mill ensures you get a consistent end product every time. This makes it the go-to choice for bioenergy producers looking to process diverse biomass materials.

Another perk is the ability to customize the output. By adjusting the size and configuration of the screen, users can control the final particle size. This is especially useful if you're planning to make pellets or prepare biomass for combustion. It gives you the flexibility to meet the specific requirements of whatever you're processing next.

When you add a biomass hammer mill to your processing setup, you’re also supporting sustainable practices. These mills improve the efficiency of biomass usage by turning waste and leftover materials into energy. This reduces reliance on non-renewable energy sources and helps lower greenhouse gas emissions. In short, biomass hammer mills play a significant role in promoting cleaner, greener energy solutions.

Choosing the right biomass hammer mill is crucial if you want to get the best performance and efficiency. Here are some things to consider:

Capacity and Size: The mill should match the volume and type of material you're working with. Bigger operations might need a larger capacity, while smaller setups can use more compact models.

Energy Consumption: You’ll want to choose a machine that doesn’t eat up too much energy, as this affects your long-term costs.

Maintenance: Look for a mill that’s easy to maintain. Less downtime means more efficient operation over time.

Investing in a high-quality biomass hammer mill can really pay off in the long run. Not only will it help you process biomass more effectively, but it also reduces waste and supports sustainable energy production. Whether you're running a large-scale industrial operation or a small facility, a hammer mill is a great tool for anyone in the bioenergy sector. It’s a smart choice if you're looking to innovate and contribute to a greener future.